If you’re new to buying aluminum parts and want to understand the benefits of a clear anodizing finish, you’ve come to the right place. This guide will help you grasp the basics of this popular finishing method and why it’s often chosen for various applications.

What Is Clear Anodizing Finish?

Clear anodizing is a surface treatment process for aluminum that enhances its properties. This process makes the aluminum more durable and resistant to damage. Here’s a simplified look at how it works:

1.Anodizing Process: Aluminum is placed in an acid bath and exposed to an electric current. This causes the aluminum to form a protective oxide layer on its surface.

2.Benefits of Anodizing: This layer makes the aluminum stronger and more resistant to corrosion. It also helps the aluminum maintain its appearance for a longer time.

Why Choose a Clear anodized coating?

Clear anodizing offers several advantages:

- Increased Durability: The anodizing process creates a hard layer on the aluminum, making it more resistant to scratches and wear.

- Enhanced Corrosion Resistance: This finish helps protect the aluminum from rust and other forms of corrosion.

- Low Maintenance: Once anodized, aluminum requires minimal upkeep. Regular cleaning is usually all that’s needed.

- Aesthetic Appeal: The clear finish maintains the natural look of the aluminium, providing a sleek and modern appearance.

How Is Clear Anodizing Applied?

Clear Anodized Aluminum Process

The clear anodizing process is quick and efficient, typically taking 1-2 hours. Here’s a step-by-step overview:

- Preparation: The aluminium part is mounted on a conductive bar for the anodizing process.

- Cleaning: The metal is cleaned in a bath to remove impurities.

- Acid Bath: The aluminum is dipped into an acid bath where fluorides react with the metal, creating a rough surface.

- Rinsing: Fluoride residues are removed in a rinse bath.

- Purification: Silicon and magnesium are removed in another rinse bath to purify the metal.

- Anodizing: A positive electrical charge is applied, creating an oxide layer on the surface.

- Sealing: The oxide coating is sealed to enhance corrosion resistance.

Comparing Clear Anodized to Raw Aluminum

- Strength: Clear anodizing makes aluminum much stronger and more durable than raw aluminum.

- Corrosion Resistance: Anodized aluminum resists corrosion much better than untreated aluminum.

- Maintenance: Clear Anodized aluminum needs less maintenance compared to raw aluminum.

Clear Anodizing vs. Other Finishes

When choosing between clear anodizing and other finishes, consider these points:

- Strength: Anodizing offers excellent strength for many applications, though other finishes might offer specific advantages depending on the use case.

- Cost: Anodizing is generally more cost-effective than many other finishing methods.

- Appearance: Anodizing maintains a clean, modern look that can be customized with various shades and finishes.

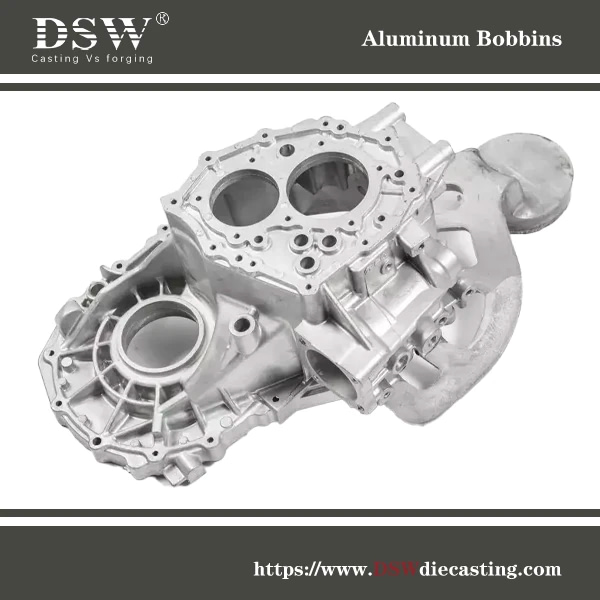

Clear Anodizing Finish in Aluminum Die Castings

When applied to aluminum die castings, the clear anodizing finish offers several advantages and changes to the surface:

Surface Changes

- Oxide Layer Formation: The anodizing process forms a thin layer of aluminum oxide on the surface. This layer is typically between 0.0001 to 0.001 inches (2.5 to 25 microns) thick.

- Improved Hardness: The oxide layer is much harder than the underlying aluminum, increasing the overall surface hardness of the part.

- Enhanced Corrosion Resistance: The aluminum oxide layer provides excellent protection against corrosion and environmental wear, significantly improving the lifespan of the part.

- Aesthetic Appeal: The clear anodized finish gives the aluminum a sleek, metallic appearance that is both visually appealing and functional. It can also be dyed to achieve various colors.

Features of the Anodized Surface

- Durability: The anodized layer is highly durable and resistant to scratches and wear. This makes it ideal for parts that experience frequent handling or friction.

- Non-Conductive: The anodized layer is electrically insulating, which can be beneficial in applications where electrical isolation is necessary.

- Thermal Stability: The anodized surface is stable at high temperatures, making it suitable for use in environments with extreme heat.

- UV Resistance: The anodized layer is resistant to ultraviolet (UV) radiation, preventing degradation and maintaining the appearance and integrity of the part over time.

- Porosity: The surface layer created by anodizing is porous before sealing, which allows for additional treatments such as dyeing or impregnation with lubricants.

- Thickness Control: The thickness of the anodized layer can be precisely controlled, allowing for customization based on specific application needs.

Clear Anodizing Process for Aluminum Die Castings

- Cleaning: The aluminum die casting is thoroughly cleaned to remove any contaminants, oils, or residues that could interfere with the anodizing process.

- Etching: The part is etched in an acidic solution to remove a thin layer of the metal, providing a clean and slightly roughened surface for better adhesion of the oxide layer.

- Anodizing: The cleaned and etched part is immersed in an electrolytic bath, typically containing sulfuric acid, and an electric current is passed through the solution. This causes the surface of the aluminum to oxidize and form a uniform, controlled oxide layer.

- Sealing: After anodizing, the porous oxide layer is sealed to enhance its protective properties. This is usually done by immersing the part in hot water or steam, which hydrates the oxide layer and closes the pores.

Benefits of Clear Anodizing Finish in Aluminum Die Castings

- Enhanced Corrosion Resistance: Protects the part from environmental damage and extends its lifespan.

- Increased Surface Hardness: Provides better resistance to scratches and wear.

- Improved Aesthetic Appeal: Offers a clean, metallic look that can be customized with various colors.

- Electrical Insulation: Useful for applications requiring non-conductive surfaces.

- Low Maintenance: The durable surface requires minimal upkeep and is easy to clean.

By applying a clear anodizing finish to aluminum die castings, manufacturers can significantly improve the performance, durability, and appearance of their products, making them suitable for a wide range of applications across various industries.

Common Uses for Clear Anodizing Finish

This finishing method is used in various industries and products:

- Building Materials: Storefronts, roofing systems, and more.

- Automotive and Aerospace: Wheel parts, control panels, and exterior panels.

- Appliances and Furniture: Refrigerators, microwave ovens, and furniture.

- Leisure Industry: Boats, golf carts, and more.

Benefits of Choosing Clear Anodizing Finish

- Durability and Strength: It provides a hard surface that withstands wear and tear.

- Health and Safety: The anodizing process is safe, and the finished product is non-toxic.

- Ease of Cleaning: Requires minimal maintenance, making it practical for both residential and industrial use.

- Cost-Effective: More affordable than many other finishing methods while offering long-term value.

How to Maintain Clear Anodizing Finish

Even though it’s low maintenance, regular cleaning helps keep it looking good:

- Use a pH-neutral cleaner: Avoid harsh chemicals that could damage the finish.

- Wipe with a damp sponge: Remove dust and dirt gently.

- Rinse and dry: Use water and a soft cloth to rinse and dry the surface.

Understanding the clear anodizing finish can help you make informed project decisions. Whether you’re working on building materials, automotive parts, or household items, this finishing method offers durability and a polished appearance.

Don’t hesitate to contact us for more information or to explore how a clear anodizing finish can benefit your needs.

No comment