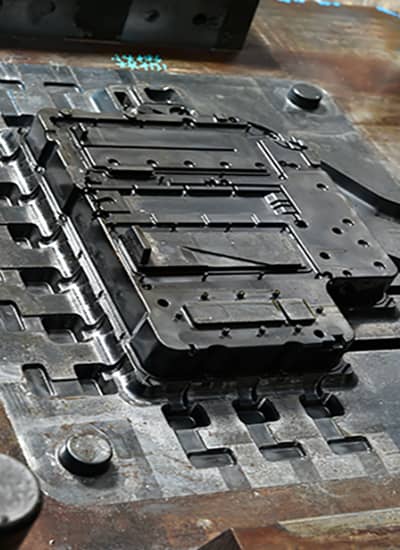

Aluminium Die Cast Tooling: Comprehensive Tool & Die Solutions

At DSW, we specialize in designing and fabricating high-quality aluminium die cast tooling, primarily produced in-house. Our 3,000-square-meter cast tooling shop is equipped with state-of-the-art machinery and staffed by certified mold-makers, each with an average of 23 years of experience. This combination of expertise and cutting-edge technology enables us to offer a full range of tooling services, including design, construction, repair, and maintenance. We are dedicated to ensuring that every tool we deliver meets the highest standards of precision, quality, and long-term performance.

Seamless Integration of Design and Engineering

Our tooling engineering teams collaborate closely with the Cast Products design team to ensure that all specifications are met while optimizing production efficiency. This integrated approach allows us to address every aspect of the tooling process, from initial design through to final execution. As a result, every tool leaving our facility reflects our commitment to innovation, with a strong emphasis on quality, precision, and reliability, ensuring dependable performance over time.

Our Tooling Capabilities Include:

- High-Pressure Cast Dies:

DSW has extensive experience and access to cutting-edge technology, enabling us to provide high-precision cast dies for a variety of manufacturing operations. Our tooling is designed to operate across die-casting machines ranging from 50 to 2,000 tons, with tool weights up to 40,000 pounds. This flexibility ensures we can meet the needs of diverse production environments, from simple to complex die designs. Our services include:- 3D Parametric Modeling: Ensuring optimal design before fabrication.

- Flow Simulations and Thermal Analysis: Advanced simulations predict material flow and analyze thermal conditions, ensuring optimal cooling and efficient production.

- Multi-Slide Dies: Designed to handle both standard and specialized slide pulls, including submarine-style and cam-actuated options, for complex part geometry.

- Internal Features: Loose-piece inserts are used for intricate internal features, enhancing casting precision.

- Conformal Cooling Lines: Tailored cooling lines reduce cycle times and extend tool life while improving production consistency.

- Documentation: We provide comprehensive die manuals and service documentation, including certificates of material conformance and heat treatment, ensuring compliance at all stages.

- Trim Dies:

Our trim dies are meticulously designed to minimize secondary operations while improving the final form and visual appeal of cast components. By focusing on automation, we enhance production line efficiency and contribute to precise final products, reducing rework and improving overall throughput. - Permanent Molds

Specializing in tilt-pour and gravity-fed permanent molds, as well as semi-permanent molds using sand core boxes, we provide tooling solutions that ensure both durability and precision. These molds are essential for producing complex die-cast parts with intricate details, contributing to efficient and accurate mass production. - Hot Forging Dies:

DSW also excels in designing and manufacturing hot-forging dies, particularly for the aerospace industry. These dies are engineered to form high-strength components for lightweight and durable automotive applications. - Fixtures and Jigs:

To optimize manufacturing efficiency, we offer custom-designed jigs and fixtures. These precision tools help streamline workflows, enhance uniformity, and ensure high accuracy in production. Our tailored solutions help manufacturers maintain consistent quality and reduce downtime on the production line.

Industries We Serve

Our tooling solutions are trusted across a wide range of industries, each with unique precision and reliability requirements. We serve:

- Aerospace & Defense: High-performance, lightweight components for demanding aerospace applications.

- Medical: Precision tooling for critical medical device components.

- Automotive: Tooling for engine blocks, transmission housings, and other automotive parts.

- Electric Vehicles: Advanced tooling solutions for electric vehicle components.

- Recreational Vehicles: Tooling for durable, high-performance components in RV manufacturing.

- Small Engine: Efficient and precise tooling for small engine production.

- Telecommunications: Tooling for precise components used in communication devices.

- Appliance: Tooling for household and industrial appliances.

- Power Tools: Precision casting mold for components used in power tool production.

- Electronics: Cast tooling for enclosures, heat sinks, and custom components in electronics manufacturing.

- Industrial Equipment: Tooling for pumps, valves, and machinery components.