Die Cast Metals

Which Die Cast Metal is the Best Choice for Your Project?

Selecting an appropriate die cast metal is of utmost importance in designing a die cast component. Here at DSW, we specialize in crafting high-quality die castings using Aluminum, Magnesium, and Zinc die cast metals. Our team of experts is ready to provide unbiased recommendations on the best die cast metal for your specific project, ensuring its success.

DSW put together this handy table comparing a bunch of die-cast metals like Al A380, AL ADC12, Mg AZ91D, Zamak3, and Zamak5. Each metal has its own perks in terms of performance and cost, so it’s crucial to chat about them before making any big decisions.

At DSW, we’re all about offering top-notch Aluminum, Magnesium, and Zinc alloys to match whatever you need for your project. Hit us up if you want to know more about what we can do for you!

When you’re picking out a die cast metal, you need to consider what your application really needs. Stuff like strength, weight, how it handles corrosion, and temperature resistance all play a role. And hey, if you need a hand, working with a trustworthy crew like CHINALCO can make all the difference in finding the perfect material.

Types of Die Cast Metal

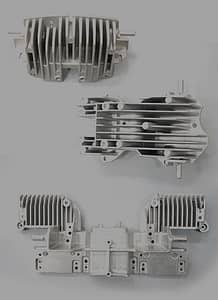

Aluminum Alloy

Aluminum is frequently employed in die casting because of its popularity and practical properties. It boasts an exceptional strength-to-weight ratio, perfect for crafting lightweight components.These alloys typically contain aluminum as the primary element, with other metals like silicon, copper, or magnesium added to enhance specific attributes. Additionally, aluminium alloy dies castings exhibit high resistance to corrosion and can endure elevated temperatures, making them well-suited for tough conditions. Aluminum alloy die castings are widely used across various industries due to their lightweight, excellent strength-to-weight ratio, and corrosion resistance.

Aluminum die castings find frequent use in a variety of applications, including but not limited to:

Automotive parts, such as engine blocks, transmission housings, and suspension components

Electronic components, such as heat sinks, enclosures, and brackets

Consumer goods, such as kitchen appliances, power tools, and sporting equipment

Magnesium Alloys in Die Casting

Magnesium is another lightweight metal commonly used in die casting. It offers high strength, good dimensional stability, and excellent machinability. Magnesium die castings are often used in the automotive and electronic industries. They exhibit excellent corrosion resistance and high-temperature tolerance, making them suitable for a diverse range of applications in various industries.

The following are some common uses of magnesium die castings:

Automotive Components include steering wheels, transmission cases, engine blocks, steering components, and structural components.

Electronic Devices, such as laptops, smartphones, and cameras.

Aerospace parts, including aircraft seat frames, brackets, housings, and structural parts. Medical Devices include orthopaedic implants, surgical instruments, and medical equipment components.

Popular Magnesium Alloys for Die Casting

- AZ91D: The most widely used magnesium alloy, AZ91D offers good strength, corrosion resistance, and castability, making it ideal for automotive and aerospace components.

Zinc Alloys in Die Casting

Zinc is a versatile metal that lends itself well to die casting complex shapes. With its exceptional strength, durability, and dimensional stability, zinc is ideal for high-precision components. Zinc alloys are valued for their ability to produce high-precision parts with complex geometries. Their low melting point (around 419.5°C) enables faster production cycles and extended mold life. Zinc alloys usually contain copper, aluminum, and magnesium to improve strength and other qualities. Furthermore, zinc die castings exhibit remarkable corrosion resistance and can be finished with a wide range of coatings and finishes. The versatility, cost-effectiveness, and range of properties offered by zinc make it a popular choice for a wide array of applications across industries.

The following are some common uses of zinc die castings.

Electronic hardware includes connectors, housings for electronic devices, switches, and various electrical components.

Hardware and locks, such as door handles and latches

Automotive parts, such as carburettor bodies, fan clutches, and brake components

Consumer Goods such as furniture hardware, lighting fixtures, buckles, zippers, toys, decorative items and fashion accessories.

Medical Equipment including instrument housings, brackets, and components for medical devices.

Popular Zinc Alloys for Die Casting

- Zamak 3: This alloy offers a good balance of strength, corrosion resistance, and ductility, making it the most widely used zinc alloy.

- ZA-27: Known for its high strength, ZA-27 is used in applications requiring greater mechanical performance.

Explore our comprehensive comparison table

of die cast metals, including Al A380, AL ADC12, Mg AZ91D, Zamak3, and Zamak5, to discover the unique benefits each one offers.

| Attribute | Al A380 | AL ADC12 | Mg AZ91D | Zamak3 | Zamak5 |

|---|---|---|---|---|---|

| Material Type | Aluminum Alloy | Aluminum Alloy | Magnesium Alloy | Zinc Alloy | Zinc Alloy |

| Primary Alloying Elements | Silicon, Copper | Silicon, Copper | Aluminum, Manganese | Aluminum, Copper, Magnesium | Aluminum, Copper, Magnesium |

| Density (g/cm³) | 2.68 | 2.68 | 1.81 | 6.65 | 6.55 |

| Tensile Strength (MPa) | 310-370 | 250-320 | 240-280 | 320-380 | 380-420 |

| Yield Strength (MPa) | 270-300 | 190-230 | 200-230 | 240-300 | 300-350 |

| Elongation (%) | 1-4 | 1-3 | 3-5 | 2-5 | 3-6 |

| Thermal Conductivity (W/m·K) | 150-170 | 130-150 | 90-115 | 118-140 | 130-150 |

| Corrosion Resistance | Good | Excellent | Good | Excellent | Good |

| Casting Method | Die Casting | Die Casting | Die Casting | Die Casting | Die Casting |

| Common Applications | Automotive parts, electronics, consumer goods | Automotive, electrical, industrial parts | Automotive components, electronics, aerospace | Electronics, hardware, automotive parts | Furniture hardware, consumer goods, automotive |

| Cost | Moderate | Moderate | Moderate | Low | Low |

Key Takeaways:

- Al A380 and AL ADC12 are both aluminum alloys suitable for a wide range of applications due to their good mechanical properties and corrosion resistance.

- Mg AZ91D is favored for its lightweight nature and excellent dimensional stability, making it ideal for automotive and aerospace applications.

- Zamak3 and Zamak5 are zinc alloys known for their versatility and cost-effectiveness, with Zamak5 offering slightly higher strength.

This table provides a clear overview of the properties and applications of each die cast metal, allowing you to make an informed choice based on your project requirements.

Choose the Right Die Cast Metal for Your Project?

At DSW, we understand that selecting the ideal die cast metal is crucial to your project’s success. Whether you need Aluminum, Magnesium, or Zinc alloys, our team of experts is here to guide you every step of the way.

No comment