Aluminum Die Casting Manufacturer

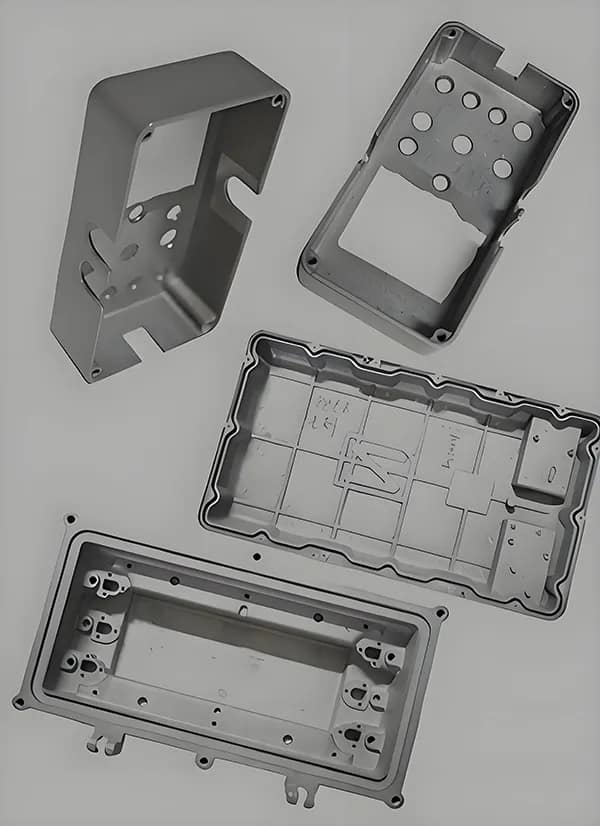

High Precision, Superior Properties, sizes range from 2 cm to 2 meters, with weights from 10 g to 38 kg.

Aluminum alloy die casting is a flexible technique that produces lightweight, durable parts with outstanding corrosion resistance, suitable for various industrial uses. Operating between 80 and 2000 tons of cold chamber machines, DSW assists clients in producing varied aluminum parts in different weights, thicknesses, forms, and sizes.

We also provide in-house design and engineering services for tool and die manufacture, ensuring high-quality and efficient production. This thorough strategy lets us control the entire process while meeting your exact requirements.

Aluminum Die Casting Manufacturing

With 16 die casting machines, DSW Industry can handle both small-batch runs and large-scale production.

This wide range allows for greater flexibility in part size, complexity, and material requirements.

Benefits of Aluminum Die Casting ?

Industries benefit from flexibility, stability, cost-efficiency, and diverse coatings.

Aluminum die casting is a perfect fit for many uses since it provides a range of advantages, including:

- Lightweight & High Strength: Aluminum die cast parts are lightweight and sturdy, with high strength-to-weight ratios.

- Superior Surface Finishes: The method allows for high-quality surface finishes, such as anodizing, and results in a smooth, polished finished product.

- Complex Part Production: Even with complex geometries, aluminum die casting allows one to create large, intricate pieces.

- High Production Rates: The process is fast, efficient, and low-cost, making it ideal for mass production.

- Corrosion Resistance: Aluminum die-cast components are highly corrosion-resistant, ensuring long-lasting performance.

- Thermal & Electrical Conductivity: The material provides excellent thermal and electrical conductivity, making it suitable for industries like automotive, aerospace, and electronics.

- Recyclability: Aluminum die castings are fully recyclable, offering both environmental benefits and cost savings.

These advantages make aluminum die casting an effective solution for a range of industries, from automotive to medical and aerospace.

Aluminum Alloy Options ?

Perfect for lighting, automotive, electronics, home appliances, and more.

Because of their excellent qualities, aluminum alloys are pretty fit for many uses. The most often used die-casting alloy, Alloy 380 (or ADC12) is flexible enough to satisfy a broad spectrum of consumer needs. We also work with several additional premium aluminum alloys, including:

Industry Standard

- A380

- A383 (ADC12)

- ADC12

- B390

- A413

- A413HP

- K-Alloy

- A360

- ADC10

- ADC6

European Standards (EN)

- EN AC-46000

- EN AC-44300

- EN AC-47100

- ENAC44300

- ENAC 47100

Special Alloys

- 43500

- AlSi12Cu

- AlSi9Cu3 (Fe)

- AlSi12Cu1 (Fe)

- AlSi12 (Fe)

- AlSi10MnMg

- AC4CH

- AlSigC3

- LM-24

- LM-27

- EZAC

These alloys are classified by industry standards, European norms, and specialized formulations used for specific applications.

Aluminum Die Casting Industrial Applications

Because of its strength, low weight, and great manufacturing efficiency, aluminum die casting finds extensive application in many different fields. The following vital sectors benefit from aluminum casting:

- Electronics

- Automotive

- Telecommunications

- Home Appliances

- HVAC Systems

- Agricultural Machinery

- Appliance Manufacturing

- Mechanical Design

These industries require parts that are durable and precise, making aluminium die casting the ideal solution for their manufacturing needs.

Methods of high pressure Die Casting

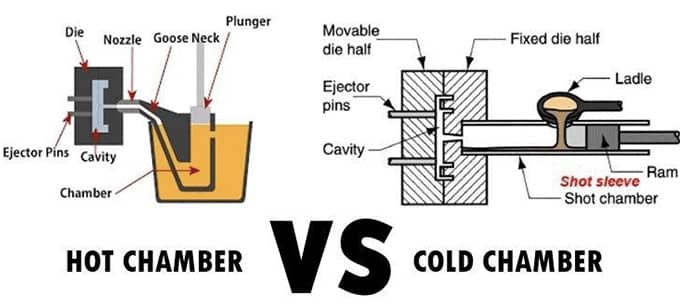

We apply both hot and cold chamber die casting techniques:

- Hot Chamber: Molten aluminum is pumped into the die via a gooseneck submerged in the molten metal, allowing effective production with high output rates.

- Cold Chamber: Molten aluminum is manually poured into a cold chamber, and a plunger forces it into the die cavity under high pressure.

Both processes ensure high-quality parts with minimal production time.

Assembly & Installation Services

For projects requiring specific assembly or installation needs, DSW offers custom solutions, including:

- Casting pins directly into the component’s design

- Machining external threads on casting bosses

- Casting holes for internal threading

- Post-machining insert installations (e.g., pins, helicoils)

- Complex Assemblies and Kitting

- Custom Coating and Finishing

- Full assembly services

Why Choose DSW?

With over 21 years of experience and ISO certification, DSW is a trusted aluminium die-casting manufacturer located in the industrial hub of Ningbo City, China. We specialize in producing high-quality, dimensionally stable parts suitable for various industries.

- Superior Quality Control: We maintain strict quality standards throughout the manufacturing process.

- Fast Delivery: Our efficient production lines ensure quick project turnaround times.

- Advanced Manufacturing: Our 11,000-square-meter facility uses the latest technology for precise and efficient production.

- Expert Engineering Support: Our team of engineers ensures every project meets high quality and functionality standards.

Custom Aluminium Die Casting

Contact DSW today for high-quality aluminium die-casting solutions.

Request a quote or learn more about our custom services.