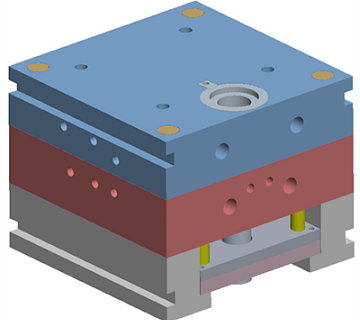

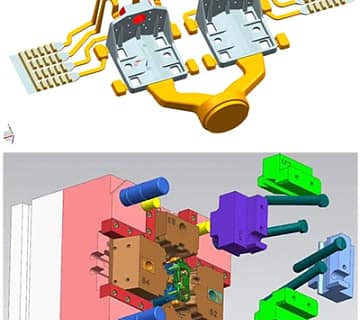

Die Casting vs. Plastic Injection Mold: A Complete Design and Tooling Comparison

A clear understanding of die casting and plastic injection mould tooling helps manufacturers improve quality and control production costs. Although both rely on precision tooling, their temperature, pressure, and material requirements differ significantly. This overview highlights key differences in gating, venting, cooling, steel selection, and ejection systems, helping engineers achieve longer tool life and consistent product performance. ... Read More