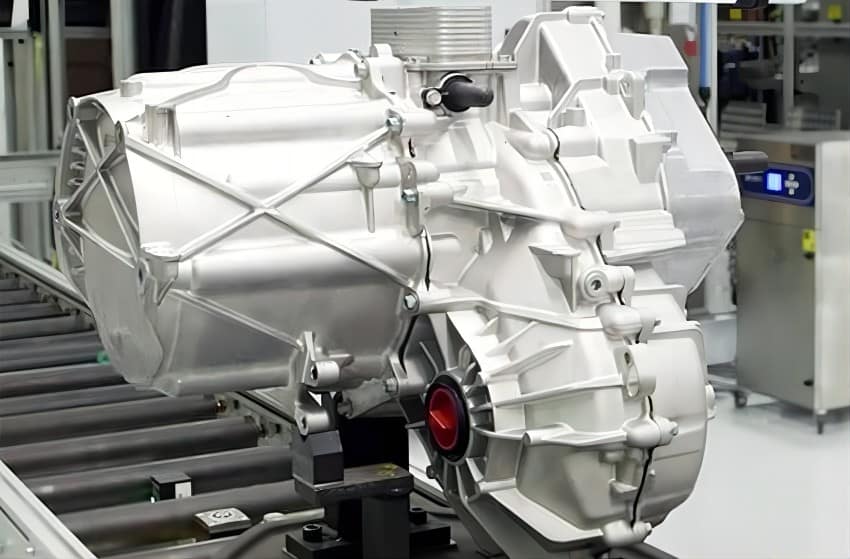

Motor Housing for Electric Car

Electric motor housings are crucial in the automotive and industrial sectors. They protect and support essential components like electric motors, inverters, and other electronic elements. These housings are vital for efficiently operating electric vehicles and machinery, protecting them from harsh environmental conditions and mechanical damage.

Specification

- Material: Aluminium alloy: A380, ADC12

- Casting Process: High-Pressure Die Casting (HPDC)

- Die Casting Machine: 800~1250T

- Weight: 3.0~5.0kg

- Dimension: Φ210220~Φ300350mm

- Annual Volume: 60,000 per year

- Porosity Requirements: ASTM E505 Level 3

- Leakage Test Requirement: Waterproof level IP67

Benefits of Casting for Aluminium Motor Housing

Cost-Effectiveness

Casting is a highly cost-effective method for mass-producing electric motor housings. It supports high production rates, reduces labour costs, and minimizes material waste.

Precision in Complex Geometries

Casting, especially die casting, allows for producing parts with intricate details, thin walls, and precise tolerances. This capability is essential for creating complex designs necessary for optimal performance.

Versatility in Materials

Casting accommodates various materials, with aluminium being the preferred choice due to its lightweight properties, excellent thermal conductivity, and corrosion resistance. This versatility enables engineers to optimize motor housings for performance and durability.

Application

- Water-cooled permanent magnet synchronous motor

- Water-cooled AC motor

- Water-cooled switch reluctance motor

- Water-cooled DC motor

- Drive Inverter Motor

Electric cars employ a variety of drive inverter motors, each chosen based on specific performance, efficiency, and cost considerations. Permanent Magnet Synchronous Motors (PMSM) and Induction Motors (IM) are among the most popular choices, offering a balance of high efficiency, power density, and robustness.

Inquiry Now

For more information and to place an order, contact our sales team today.

Ensure your electric vehicles and machinery are equipped with the best quality aluminium motor housings for optimal performance and efficiency.

Reviews

There are no reviews yet.