Unveiling Surface Finishes: Delving into Chromate and Chrome Options

Surface finishing is a crucial step in manufacturing. It enhances both the appearance and functional properties of parts. The choice of finish depends on the application, desired appearance, and required protection against environmental factors.This blog will offer a detailed and informative look at chrome and chromate surface finishes. You’ll discover the variety of chromate plating options, their colors, levels of corrosion resistance, and various applications.

Detailed Explanation of Chrome and Chromate Finishes

Chrome Plating

- Types of Chrome Plating:

- Bright Chrome: Known for its mirror-like finish, bright chrome is used in automotive parts, household fixtures, and decorative items. It provides excellent corrosion resistance and wear life.

- Satin Chrome: This finish has a subdued, matte appearance while maintaining the protective qualities of bright chrome. It is preferred in applications where a less reflective surface is desired.

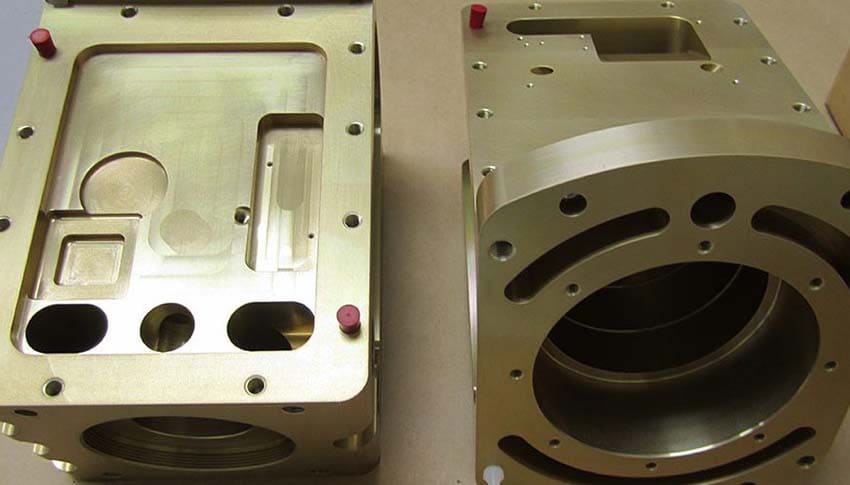

- Hard Chrome: Hard chrome plating is not covered in the original text; it is used for industrial applications requiring high wear resistance and low friction. It is commonly applied to machinery parts, tools, and molds.

- Application Process:

- Chrome plating involves electroplating a layer of chromium onto a metal object. The process typically includes pre-treatment steps such as cleaning and polishing, followed by plating layers of copper and nickel before applying the chromium layer.

Chromate Conversion Coatings

- Types of Chromate Finishes:

- Clear Chromate: Offers a slightly iridescent blue hue and provides moderate corrosion resistance.

- Yellow Chromate: Known for its gold-to-brownish appearance, it offers enhanced corrosion protection.

- Black Chromate: Provides a distinctive black finish with good corrosion resistance.

- Olive Drab Chromate: Characterized by a dark green finish, it can withstand up to 150 hours of salt spray testing without white corrosion.

- Trivalent Chromate: A safer alternative to traditional hexavalent chromates, trivalent chromate offers similar protection without environmental and health hazards. It is commonly used in automotive applications and exceeds many industry standards.

- Chromate with Zinc:

- This process involves applying a zinc coating to a part, followed by a chromate conversion coating. The zinc acts as a sacrificial layer, corroding before the base metal, thus providing enhanced protection.

- Chromate without Zinc:

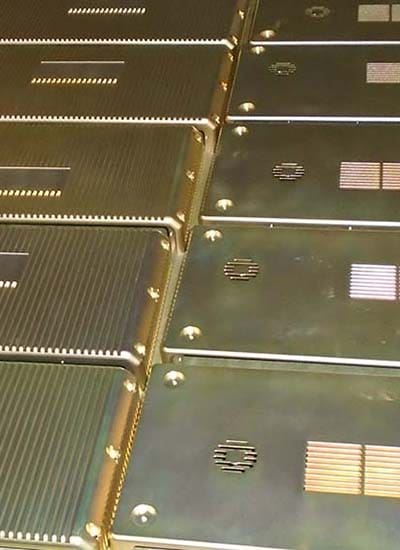

- Chromate coatings can also be applied directly to metals like aluminum and zinc die-casts. These coatings are very thin and do not add measurable thickness to the parts, making them suitable for precision applications.

Differences between chrome finishes and chromate finishes

| Attribute | Chrome Finish | Chromate Finish |

| Nature and Composition | Metallic element (chromium) applied via electroplating | Chemical compound (chromate ion) used in conversion coatings |

| Application Process | Electroplating with layers of copper, nickel, and chromium | Immersion in a chromate solution, chemical reaction on metal |

| Appearance | Shiny, mirror-like; bright or satin finish | Dull with possible iridescence; clear, yellow, black, olive drab |

| Corrosion Resistance | Moderate corrosion resistance, aesthetic focus | High corrosion resistance, protective passivated layer |

| Thickness and Durability | Adds measurable thickness; durable and wear-resistant | Very thin, minimal thickness addition; excellent corrosion resistance |

| Environmental Impact | Hexavalent chromium is toxic; trivalent chromium safer | Hexavalent chromate toxic; trivalent chromate less hazardous |

| Typical Applications | Decorative and functional uses (automobiles, furniture) | High-corrosion environments (aerospace, military, marine) |

Benefits of Chrome and Chromate Finishes

- Corrosion Resistance: Both finishes offer excellent corrosion protection, with chromate finishes enhancing the sacrificial protection of zinc coatings.

- Aesthetic Appeal: Chrome finishes provide a high-gloss, reflective surface, while chromate finishes offer a range of colours and sheens.

- Durability: Chrome plating, tough chrome, significantly improves the wear resistance and lifespan of parts.

- Environmental Considerations: Trivalent chromate finishes are more environmentally friendly than traditional hexavalent chromates, meeting stringent environmental regulations.

Applications of Chrome and Chromate Finishes

- Automotive Industry: Chrome plating is widely used for trim, grills, and other decorative parts, while chromate finishes are used for under-the-hood components and fasteners.

- Aerospace: Both finishes are used for parts requiring high corrosion resistance and durability.

- Consumer Goods: Chrome and chromate finishes are often used in household fixtures, electronics, and furniture for their aesthetic and protective properties.

- Industrial Equipment: Hard chrome plating is essential for machinery parts, tools, and molds to extend their operational life and performance.

Choosing the Right Surface Finish

Choosing the suitable surface finish for your parts can significantly impact their performance, appearance, and longevity. Chrome and chromate finishes offer versatile solutions for various applications, balancing aesthetics, protection, and environmental considerations. Contact our design engineers to explore the best surface finishing options if you have specific requirements or need further assistance.

No comment