Zinc for Casting

Zinc is a popular choice in the casting industry due to its favorable properties. With a low melting point of around 380°C (716°F), it enables efficient die casting processes while minimizing energy consumption and equipment wear. Zinc’s excellent corrosion resistance ensures the longevity of cast components, making it ideal for various applications in automotive, electronics, and construction.

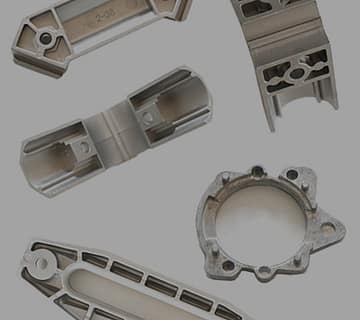

Additionally, zinc alloys offer a high strength-to-weight ratio, allowing for lightweight yet robust parts. The material can achieve intricate shapes and fine details, providing designers with flexibility without compromising structural integrity. Overall, zinc is a reliable and economical option for casting, combining performance, durability, and cost-effectiveness across multiple industries.

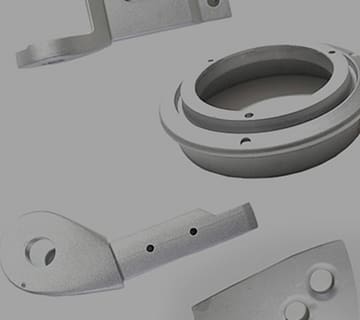

How to Design Zinc Alloy Die Castings